How To Price Table Linens To Sell

If you’ve made any of the following products from my tutorials, and you want to start selling them, the next step is to ensure you can be profitable.

- How To Sew a Square Coaster (Free Pattern & Beginner-Friendly)

- How to Sew Placemats to Sell (with Mitred Corners)

- How To Sew A Casserole Hot Pad with a Mitered Hem

- How to Sew Hot Pads to Sell (with mitered hem)

- How To Sew a Casserole Cozy (free pattern)

- How To Sew a Waterproof Casserole Cover

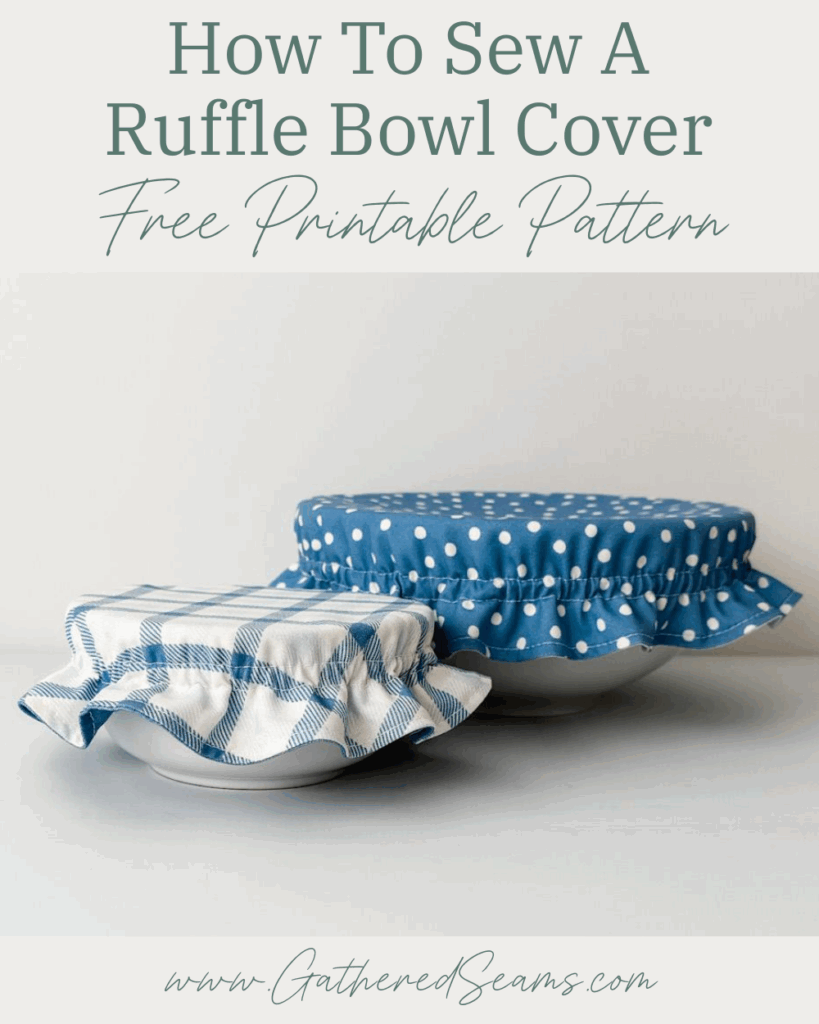

- How To Sew Waterproof Bowl Covers (free pattern)

- How To Sew Napkins to Sell (with mitered corners)

- How To Sew Napkin Rings to Sell

This article outlines how I would price each item to start, using a basic pricing formula. Your numbers and the way you price should change as you run your business and have clear numbers for overhead costs and wages.

Don’t make this pricing mistake

Most handmade business owners don’t want to bother with tracking all their business expenses or get paid for every hour they work on their business.

If you don’t work these costs and wages into your prices, you won’t have profits. And if you don’t have profits, you can’t:

- pay yourself more than an hourly wage (you’re simply being paid for hours in…if that)

- get through low-sales periods – your business will go through peaks and valleys. Profits ensure you don’t have to shut down when sales are low.

- take vacations or sick days – you’ll need time off and profits will float you through those times.

- grow your business – profits allow you to invest in your business and spend more money on bigger craft shows, more or better materials, better tools, etc.

Factors that increase or decrease what you can charge

Products range in price due to several elements, including:

- Target market – if you’re making hot pads to market as gifts, consumers may not want to pay as much as eco-conscious shoppers who want hot pads made of organic, sustainable materials for their eco-friendly home.

- Materials – if you’re using a lower-quality material (e.g. quilting cotton) and batting with minimal protection, you won’t be able to charge as much as if you’re using a premium fabric (e.g. organic linen) and batting with more protection.

- Craftsmanship – the more advanced your sewing skills are, the more polished your hot pads/potholders will look, which will allow you to charge more. For example, a basic hot pad with no mitered hem or binding should cost less.

- Branding – you may create a luxury brand and the elements that surround your hot pads/potholders, such as tags, packaging, website design, etc. can increase the price and help shoppers place a higher value on your items.

The importance of buying in bulk

The prices suggested in this article are based on average costs when buying materials in bulk. Here are a few examples:

- Cotton

- Batting

- Heat-resistant batting

- Food-safe PUL

- Fusible Interfacing

Based on these sources, I’m using the following prices for my calculations:

- Cotton = $4.99/yard

- Cotton batting = $5.99/yard

- Thermal batting = $6.99/yard

- Food-safe PUL = $6.50/yard

- Bias tape (made from cotton @ $4.99/yard) = $0.25/yard

- Fusible interfacing = $1.85/yard

Some materials, such as thread, will be used to make dozens of items. You can either estimate how many items you can make with each multi-use material, or, if the costs will be less than $0.01, you can assume those prices will be covered by the markups.

How to price coasters to sell

Below is an example of how I would calculate production costs for a basic coaster.

I would then use those production costs to plug into the beginner pricing formula,

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

From 1 yard of fabric, I can make 28 coasters.

Cotton = $0.18/coaster

Batting = $0.21

Total material costs per coaster = $0.39

Wages: $15/hour

Each coaster takes 5 minutes to make

*Find tips below to sew items faster

Wages = $1.25 / coaster

Total Production Costs = $1.64

$1.64 x 2 = $3.28 (wholesale price)

$3.28 x 2 = $6.56 (retail price)

I might bump that price slightly up or down, depending on my overhead costs.

Price of coasters

Based on the material costs outlined at the top of this article, I would price as follows:

$6 – $7 per coaster

I would bundle my coasters to increase the value per transaction (VPT) and to cater to how consumers tend to buy coasters (i.e. in sets).

Pack of 4 coasters = $20 ($5/each)

Pack of 6 coasters = $28 ($4.67/each)

Pack of 8 coasters = $36 ($4.50/each)

Applying a greater discount for bigger packs will encourage more people to buy more.

How to price placemats to sell

Below is an example of how I would calculate production costs for a placemat.

I would then use those production costs to plug into the beginner pricing formula.

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

From 1 yard of outer fabric I can make 2 placemats.

From 1 yard of batting I can make 4 placemats

Cotton = $2.50/placemat

Batting = $1.40/placemat

Total material costs per placemat = $4

Wages: $15/hour

Each placemat takes 12 minutes to make.

Wages = $3/placemat

Total Production Costs = $7

$7 x 2 = $14 (wholesale price)

$14 x 2 = $28 (retail price)

I might bump that price slightly up or down, depending on my overhead costs.

Price of placemats

Based on the material costs outlined at the top of this article, I would price as follows:

$25 – $30 per placemat

If I wanted to lower the cost of my placemats, I would skip the batting.

I would bundle my placemats to increase the value per transaction (VPT) and to cater to how consumers tend to buy placemats (i.e. in sets).

For example:

Pack of 2 placemats = $54

Pack of 4 placemats = $100

Pack of 6 placemats = $144

Applying a greater discount for bigger packs will encourage more people to buy more.

How to price hot pads to sell

Below is an example of how I would calculate production costs for a medium-sized hot pad.

I would then use those production costs to plug into the beginner pricing formula.

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

I’m making a medium-sized hot pad (approx. 10” x 10” finished).

From 1 yard of outer fabric I can make 4 hot pads.

From 1 yard of batting I can make 9 hot pads.

From 1 yard of thermal batting I can make 9 hot pads.

Cotton = $1.25/hot pad

Cotton Batting = $0.67/hot pad

Thermal batting = $0.78/hot pad

Total material costs per placemat = $2.70

Wages: $15/hour

Each hot pad takes 10 minutes to make.

Wages = $2.50/hot pad

Total Production Costs = $5.20

$5.20 x 2 = $10.40 (wholesale price)

$10.40 x 2 = $20.80 (retail price)

I might bump that price slightly up or down, depending on my overhead costs.

Price of medium-sized hot pad

Based on the material costs outlined at the top of this article, I would price as follows:

$20 – $22/hot pad

I could sell these in sets of small, medium, and large, offering a small discount.

How to price bowl or casserole covers to sell

Below is an example of how I would calculate production costs for a large bowl cover (which would be similar to a casserole cover, with the casserole cover requiring slightly more materials).

I would then use those production costs to plug into the beginner pricing formula.

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

From 1 yard of fabric I can make 6 large bowl covers.

From 1 yard of food-safe PUL I can make 6 large bowl covers.

Cotton = $0.83/cover

Food-safe PUL = $1.08

Bias tape = $0.38 (approximately 1.5 yards needed)

Total material costs per cover = $2.29

Wages: $15/hour

Each bowl cover takes about 10 minutes to make

*Find tips below to sew items faster

Wages = $2.50

Total Production Costs = $4.79

$4.79 x 2 = $9.58 (wholesale price)

$9.58 x 2 = $19.16 (retail price)

I might bump that price slightly up or down, depending on my overhead costs.

Price of a large bowl cover or casserole cover

Based on the material costs outlined at the top of this article, I would price as follows:

$20 – $22 per large cover

$22 – $24 per casserole cover

I would bundle my sets to increase the value per transaction (VPT). I could lower the price slightly to encourage set purchasing.

How to price napkin rings to sell

Below is an example of how I would calculate production costs for a napkin ring.

I would then use those production costs to plug into the beginner pricing formula.

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

From 1 yard of fabric I can make approximately 16 napkin rings.

From 1 yard of fusible interfacing I can make 36 napkin rings.

Cotton = $0.31/napkin ring

Food-safe PUL = $0.05

Total material costs per cover = $0.36

Wages: $15/hour

Each napkin ring takes about 10 minutes to make.

*Find tips below to sew items faster

Wages = $1.50

Total Production Costs = $1.86

$1.86 x 2 = $3.72 (wholesale price)

$3.72 x 2 = $7.44 (retail price)

I might bump that price slightly up or down, depending on my overhead costs.

Price of a napkin ring

Based on the material costs outlined at the top of this article, I would price as follows:

$7 – $8 per napkin ring

I would bundle my napkin rings into sets (4, 6, or 8) and I could discount the price per ring slightly, or use the lower price point.

For example, a set of 6 napkin rings, I might charge $42 ($7 each) or $40, which discounts the set by about 5%, making each ring $6.67/each.

How to price napkins to sell

Below is an example of how I would calculate production costs for a cloth napkin.

I would then use those production costs to plug into the beginner pricing formula.

Cost would go up if you’re using different materials or adding more details.

When sewing to sell, it’s essential to buy materials in bulk to get a low price or wholesale price. Links to resources are at the top of this article.

Material Costs

From 1 yard of fabric I can make 4 napkins (18″ x 18″).

Cotton = $1.25/napkin

Total material costs per cover = $1.25

Wages: $15/hour

Each napkin takes about 5 minutes to make.

*Find tips below to sew items faster

Wages = $1.25

Total Production Costs = $2.50

$2.50 x 2 = $5 (wholesale price)

$5 x 2 = $10 (retail price)

Price of a napkin ring

Based on the material costs outlined at the top of this article, I would price as follows:

$10/napkin

However, I wouldn’t sell each napkin individually; I would sell them in sets of 4, 6, and 8.

I could set my prices to $40, $60, and $80, or discount the sets slightly (5% – 10% discount); $38, $56, $72,

How to lower costs

If you’re looking at that price and feeling like it’s too high for your target market, you can lower your costs by:

- Using a simpler pattern – mitered hems and bindings add extra materials and time. By simply sewing the top and bottom together, with right sides together and leaving an opening to turn right side out, then top-stitching, you can reduce your materials and time.

- Smaller sizes – stick to the smaller size of hot pads, which may allow you to use your scraps of fabric.

- Fabric choices – you might use a lower-priced fabric for the bottom piece of fabric.

Here are a few general ways to spend less money on materials and time on production (without compromising quality).

- Buy materials in bulk – retailers will often provide discounts when you buy more.

- Watch for sales – I sign up for my favorite fabric stores’ newsletters so I know when they’re having a sale.

- Save on shipping costs – if you buy from online retailers, look for ones that have lower shipping fees, and try to buy in bulk so you meet their free shipping threshold (e.g. spend $150 to get free shipping) or so that you’re not paying as much by having dozens of packages shipped to you in a month, instead of one.

- Batch your work – if you make one placemat at a time, you’ll slow down your production time significantly. Instead, cut fabric for dozens of placemats at once, then sew the first step for all placemats at once, then complete the second step for all placemats, etc.

- Use time-saving tools – As your business grows, invest in tools that help you create products faster. Such as:

- rotary cutter, mat, and fabric weights

- wool mat so I don’t have to get up to press pieces

- point turner to easily turn corners

Costs to Cover

1 – Production Costs & Wages

Money (including wages) you spend on materials that make your products.

For example:

- fabric

- batting

- thread

- sew-in label

- hourly wage for time spent to make the product

2 – Overhead Costs & Wages

Money you spend on business costs and wages outside of production.

For example:

- craft show booth fees

- materials for your craft show display

- Etsy fees

- materials for shipping

- marketing materials (e.g. business cards)

- wages for time spent posting to social media, setting up and selling at a craft show, shipping products, etc.

3 – Shipping (optional)

If you sell online, consider shipping costs.

One way or another, the customer always pays for shipping. It’s either a fee that gets added to their shopping cart total, or it’s built into the product’s price (either partially or fully).

When to put shipping fees in product prices

Imagine you’ve added a $20 item to your shopping cart, and you go to check out and see that shipping is $15. Most people will abandon their cart and decide not to buy from that business.

On the other hand, if you place a $30 item in your cart and are asked to pay $5 for shipping, that seems more reasonable.

It’s easier to increase the perceived value of a product (i.e. get shoppers to think an item is as valuable or more valuable than the price listed through high-quality branding, packaging, photography, etc.).

It’s harder to do that for shipping. No one wants to spend money on shipping; it feels like a penalty.

So it’s often better to increase the price of your products slightly to absorb some or all of the shipping fees.

The customer is paying the same amount at the end of the day, but psychologically, they’ll feel better about, perceivably, all $30 going toward the product, rather than shipping.

Pricing formula

When starting your business, a simple pricing formula is ideal because you don’t know what your monthly and yearly overhead costs and wages will be.

Once you’ve been operating your business, and you know your costs and wages, then it’s important to check back in on your prices to ensure you’re covering all your costs and wages and (eventually) making a profit.

Material + Time = Production Costs

Production Costs x 2 = Wholesale Price

Wholesale Price x 2 = Retail Price

Wholesale Price is the price you will sell your products to retailers at (they typically expect a 50% discount because they buy multiple items in an order and must profit when they resell your items in their stores. Even if you don’t plan to sell your products wholesale to retailers, it’s a good idea to have a wholesale price and retail price because it will allow you to offer discounts and run end-of-season/year sales, and still profit.

This basic formula doesn’t require you to know your overhead costs and wages and to work them into your product’s prices.

It simply assumes that by multiplying each of your product’s production costs by 2, you’ll be covering your overhead costs and wages and making a profit.

It’s important to check in regularly to ensure that’s true and you’re not losing money.